Machine shops can serve a variety of purposes, as the term refers to anywhere that machining takes place. This means that as long as your shop takes raw materials and converts them to a different shape and size, it is a machine shop. Machine shops can include inspection equipment, welding machines, drill presses, milling machines, metal lathe machines, grinding machines, and more. Machine shops can be part of numerous industries, from aircraft to automotive to customized parts.

The Poor Air Quality Typical of Machine Shops

Unfortunately for those who work in machine shops, as well as those who run them, the metalworking that is so common in machine shops can generate pollutants and debris. Just some of the potential pollutants include hexavalent chromium, lead, and manganese in fumes, as well as dust and oil mist. The risk associated with these pollutants and debris is so strong that OSHA carefully monitors metalworking facilities and has regulations in place for air quality.

Most of the air quality issues associated with machine shops are from fumes and weld smoke. The specific problem depends on the materials and processes used. Generally, welding results in between 1 and 2 percent of the metal for weld-joining becoming particulate that can collect. It increases to 6 to 8 percent for aluminum welding.

How Poor Machine Air Shop Quality Can Affect Workers’ Health

In addition to the need to improve air quality enough to meet OSHA standards, improving the air quality at machine shops is in the best interests of the workers and owners.

OSHA reports that workers who are exposed to welding fumes for brief periods of time can experience nausea, dizziness, and irritation of the throat, nose, and eyes. With prolonged exposure, there is a risk of lung damage as well as cancer in the lungs, urinary tracts, or larynx. It is also possible for some machine shop fumes to cause nervous system damage, kidney damage, stomach ulcers, or metal fume fever over time. In confined machine shops without proper ventilation, there is also the risk of carbon dioxide, argon, or helium levels in the air increasing, causing suffocation.

Welding is not the only issue, as some of those issues are shared with other types of machining. Machining also commonly uses lubricants or fluids that can lead to fine mists of oil in the machine shop. They can irritate the lungs, throat, nose, skin, or eyes when inhaled. Longer exposure can result in chronic bronchitis, asthma, cancer, lung fibrosis, and impaired lung functionality. There is also a slip-and-fall risk.

Employees are more likely to be satisfied with their workplace if they do not have to worry about safety concerns. This prevents the need for repeatedly wasting time to hire and train new workers. Additionally, healthy employees will be more productive and less likely to have to take time off work.

As a bonus, improving the shop’s air quality can also help with certain tasks. For example, shops that use laser welding may notice lower-quality parts if there is too much smoke in the air, as this can reduce the intensity and delivery of the beam to the part.

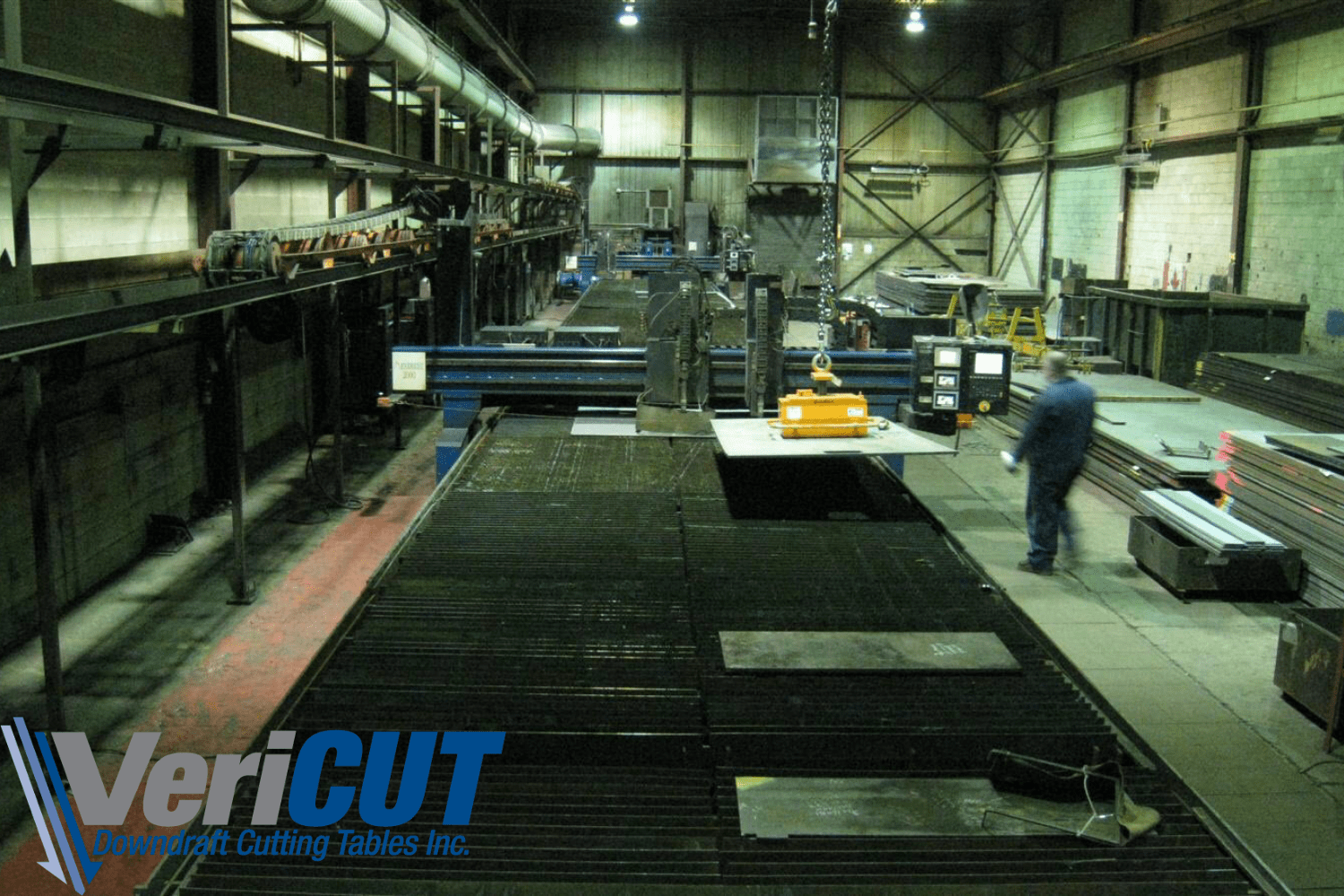

How Custom Downdraft Tables Offer a Solution

One of the most effective and simplest solutions to improve air quality in machine shops is to utilize downdraft tables. Downdraft tables are upgraded versions of typical workbenches that include built-in ventilation to draw dust, smoke, and fumes away from the materials and the workers. The result is dramatically improved air quality.

Improve Worker Health

By improving the air quality, downdraft tables improve the health of workers. They reduce the risk of the various health-related problems that workers could experience from inhaling smoke and dust, such as eye irritation, asthma, sneezing attacks, continuous coughing, throat or lung cancer, and sneezing attacks.

Benefits of Improved Worker Health

As mentioned earlier, having healthier workers improves employee retention and satisfaction, reduces sick days, improves productivity, and can reduce claims for worker’s compensation.

Specific Advantages with VeriCUT

VeriCUT’s downdraft tables are engineered to uniformly and effectively draw smoke away across the entire width of the table. This can even include smoke that is up to two or three feet higher than the table. That ability reduces the risk of the dust, smoke, and fumes spreading throughout the rest of the shop. The VeriCUT Downdraft System also has a dust recovery rate of up to 99% and air ducts with a capacity that is 40% greater than the standard size.

Start improving the air quality in your machine shops by exploring downdraft tables and other options from VeriCUT.