A downdraft table works as a self-contained filtration system. It’s not only portable, but also customizable and multipurpose – in that, you can also use it as your workstation, dust collectors, and fume extractors. Simply put, downdraft tables will remove harmful particulates from the immediate environment and replace dusty air with filtered, breathable air. You will discover how they work and the way they can be customized for lower operating costs and better performance.

What Are Downdraft Tables?

Consider these as indoor air quality devices that work without external ventilation. They will draw-down air during finishing processes, such as welding, sanding, and grinding. Thus, the dust-laden air and fumes can be removed from the breathing zones of workers. The filters on downdraft tables can snatch up particles as small as .5 microns. Pulse-jet blasts of compressed-air ensure that those filters function at peak operational efficiency.

What Are the Different Types of Downdraft Tables?

The two basic types are wet and dry downdraft tables. Wet downdraft tables have both a liquid – usually water, and a standard filter element. They are more commonly employed for the capture of flammable/explosive metal dust. On the other hand, dry downdraft tables have only a standard filter element that catches smoke, fumes, and vapors.

Why Do We Need Downdraft Tables?

Workers can use a downdraft table as a working bench. Before starting a finishing process, such as sanding, they switch it on. That creates a downdraft airflow, which will catch the debris they remove and suck it down. This prevents the dust from ending up in the eyes, nose, or lungs. Additionally, any shavings and bits of materials will also get sucked down. Consequently, the working area remains clean and provides maximum visibility to workers.

Where are they used?

Generally, downdraft tables are perfect for the following applications:

- Sanding & Woodworking: They produce fine dust that can be easily inhaled and cause health issues later on.

- Welding: particularly heavier-duty welding applications, such as MIG, TIG, and stick welding. A downdraft table will reduce the risk of inhalation of carcinogenic fumes.

- Deburring: Abrasives used in polish or finishing can produce toxic/hazardous fumes.

- Grinding: Involves the production of fine particles from the metal and plastic refuse.

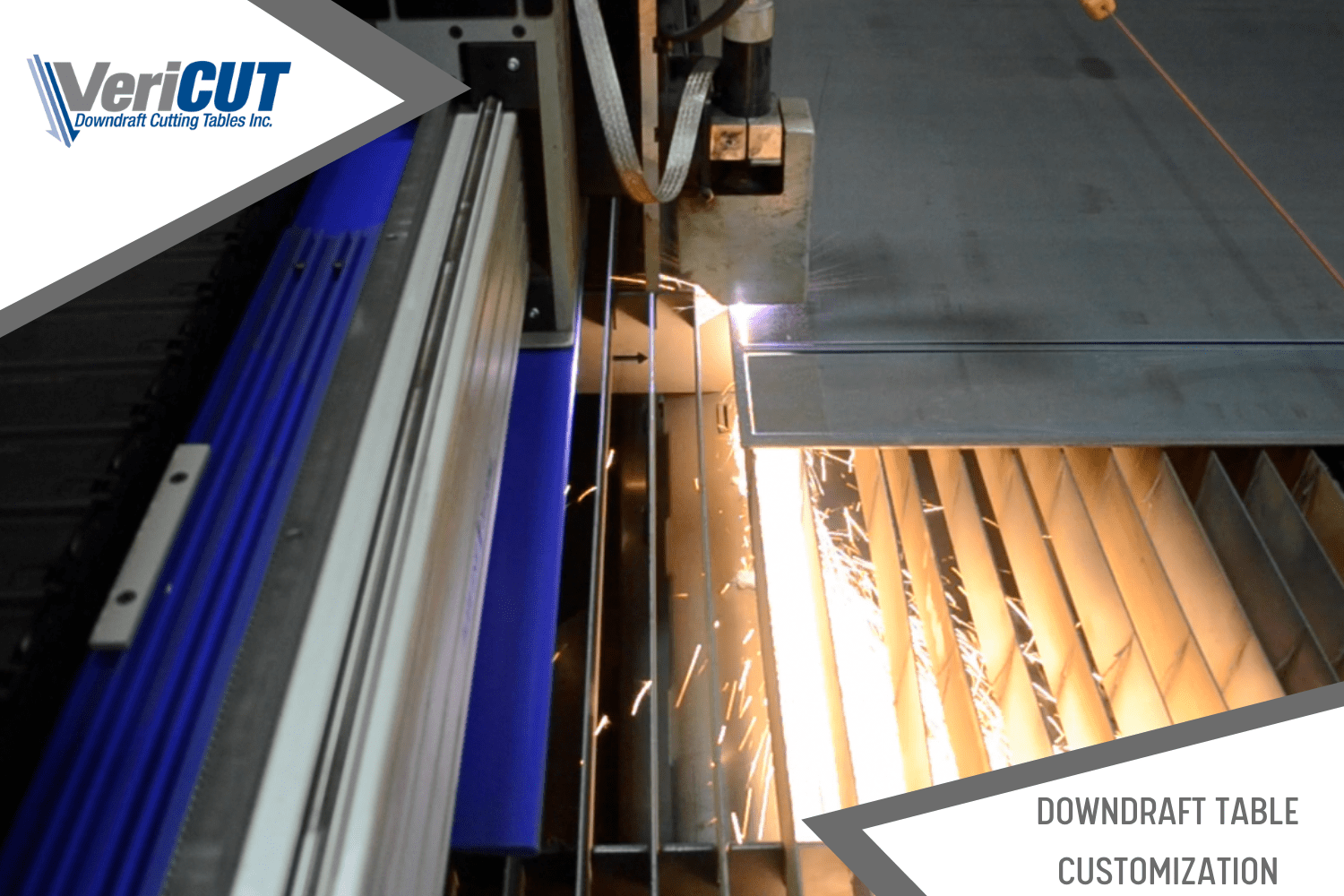

- Cutting: More specifically plasma cutting – a cleaner table can improve overall productivity

- Mixing: To prevent the powders and granules in use escaping into the air and into the workers’ lungs.

- Chemical Preparation & Processing of Explosive Materials

How Do Downdraft Tables Work?

Essentially, a downdraft table will suck in air and force it through a filtration system. The dust particles and impurities get deposited in a collection area for disposal. The resulting exhaust then consists of clean air.

Benefits of Downdraft Tables

A feature that makes sure downdraft tables stand out from other dust collecting systems is that they also get rid of fumes. Some relevant benefits based on specific applications include:

- The personnel at small welding firms, can prevent endangering their well-being due to the carcinogenic fumes their job exposes them to.

- Woodworkers run higher risks of injuries in cluttered workspaces. Downdraft tables can help take care of that problem by maintaining a clean surface area.

- Fitting a downdraft table with a filter for solid particles can protect those who work with metals. They face a lowered chance of injuring themselves on metal chips or inhaling metallic particulates.

- For more specialization, an industrial custom downdraft table can also be equipped with heavy-duty work surfaces, spark guards, and exhaust chimneys.

Find other benefits these tables can provide for your employees.

The VeriCUT Difference

Our experts are well-known for the crafting of the unique and custom downdraft table for every client. Two main traits set our downdraft tables apart from the others:

- A revolutionary zonal design

- Continuous improvement

VeriCUT creations are based on zone-by-zone ducting design. Simply put, that means your dust collection system clears the area immediately affected by cutting. There’s a clean workspace at all times and the custom downdraft table fulfills its capacity requirements while reducing the energy needed to do so.

The results of these innovations are:

- Reduced air make-up costs

- About 40% larger capacity and thus, higher dust recovery rates

- ROI in under 8 months

- About 7-80% lower operating costs

- Close to 100% greater green-light operating time

- Almost zero maintenance time and efforts

Find out more about possible customization options that specifically suit the way your employees will be using a custom downdraft table here. If you have any further questions regarding a custom downdraft table feel free to contact us, and we’ll get in touch with you as soon as possible.

January 6, 2021