Whether you are cutting, sanding, or building, you will create dust. Whether your shop is a small, one-man operation or a multi-billion dollar industry, you will create dust. This is why investing in a downdraft table dust collection system is vital to save you valuable time and money in the long term for your equipment.

Downdraft dust collection works on the basic notion of “capture and collect”. These systems collect airborne dust particles, fumes, and impurities to keep your shop environment clean and safe. These systems work to eradicate the dust, debris, and fumes that your machinery creates, keeping your space clean and safe at all times.

There are many reasons to invest in a downdraft table dust collection system such as health, safety, employee morale, increased production, improved equipment maintenance, finishing quality, lower custodial costs, and the fact that it can pay for itself in less than a year.

- Breathing in smoke and dust is harmful to the body and can cause health issues in the throat, nose, ears, and eyes. Investing in a downdraft table dust collection system is contributing to the health of all those in your shop’s environment.

- Dust in an environment can become unsafe very quickly; it creates a slipping hazard and impacts visibility. Imagine if dust never flew into the air, but was captured and collected into a canister below your machinery. No danger, and better, breathable air.

- When an environment is free from dust, debris, and fumes, your employees will feel safe and appreciated. This will boost your employee morale, making your shop a better and more productive place to work.

- Not only does a downdraft table dust collection system make for happier and more productive employees; this also makes you money. Increased productivity means increased profit. A clean work environment promotes higher yield as workers have ameliorated visibility, leading to more precise measurements and assemblies.

- While your productivity is increased, and you’re making more revenue, the downdraft table dust collection system will also help you cut costs on equipment maintenance. Because your machinery isn’t constantly being overloaded with dust and debris, it will need fewer repairs. Without the wear and tear of dust, it will function with more precision and longevity.

- If you’re still not sold, another reason to invest in a downdraft table dust collection system is the improved finishing quality. With no dust in the way, lines will be cut more precisely. Further, if anything is stained, varnished, polished, or painted, there is no risk of it being ruined by dust implanting itself into your beautiful finishes.

- It goes without saying that if your dust, debris, and fumes are being collected, your custodial costs will fall tremendously. No more scrubbing or spending hours dusting and sweeping. Simply empty the canister when it fills.

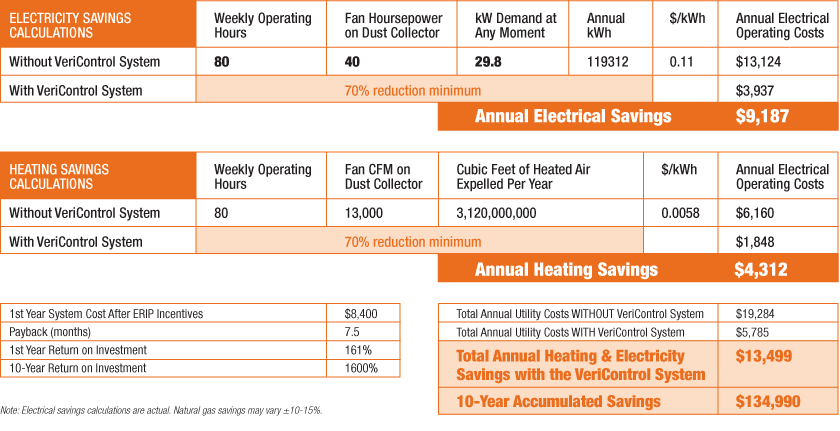

- According to studies done about the use of the VeriCUT Crossflow™ downdraft system, there was a minimum reduction of 70% in annual heating and electrical costs.

Furthermore, there is a typical ROI of a short 7.5 months for metal and woodworking shops, shops in the pharma, cosmetic, food, and commercial industry as well as for laser and plasma cutting tables.

While the initial cost of a downdraft table dust collection system is high, your investment will be returned within the year through savings in custodial work, equipment maintenance, and heat and electric costs while you also see a rise in productivity and finishing quality.

Call VeriCUT today to improve the quality of your environment and product with a downdraft table dust collection system.

September 16, 2019