Metal downdraft tables are increasingly popular in workshops that generate a lot of dust and fumes on their work surfaces. They pull contaminated air away and downward, removing it from the worker’s breathing area and preventing dirt and debris from building up on fixtures and equipment. Cutting, grinding, and welding are all applications that can be made safer and more efficient by installing a downdraft table.

How a metal downdraft table works

Downdraft tables are built-in ventilation systems for workstations. They are designed to catch and filter dust, smoke, and fumes. A blower installed under the table’s surface sucks in the air, which is enclosed in an airtight space to prevent contaminants from getting out. The air is then filtered through the ventilation system to eliminate any impurities before being sent back into the environment.

What are the health and safety benefits of metal downdraft tables?

Downdraft tables accomplish two important workplace goals: protecting employees and meeting industry-specific workplace standards. VeriCUT’s mechanical systems will deliver the following health and safety benefits to your facility:

- Minimize employee exposure to contaminated air. A metal downdraft table can help prevent coughing, sneezing, and throat phlegm build-up triggered by exposure to airborne pollutants. Your employees won’t be forced to take production-limiting sick days or risk serious illnesses like lung and throat cancer, asthma, emphysema, bronchitis, and eye irritation, all of which can inspire workers’ compensation claims and lawsuits.

- Meet your legal obligations. There are laws and regulations in place that require employers to provide a safe and healthy work environment. By eliminating dangerous dust and smoke from your building, you can meet your legal obligations and avoid fines and sanctions by industry regulators.

- Eliminate fire and explosion hazards. Many types of industrial dust are flammable or combustible. Plasma and oxy-acetylene dust in particular represent a serious fire risk, so if you do a lot of welding and cutting, installing an automatic downdraft table is a proactive move that can protect your workforce and prevent property damage.

Our industrial downdraft cutting tables make sure that you’re up for the challenge of maintaining high air quality in a busy machine shop. By capturing and removing dust and smoke at the source, you’ll enjoy the following advantages:

- Manufacture quality products without putting the building at risk for a dust fire or explosion

- Prevent dangerous powders and granules from getting into the air during mixing operations

- Eliminate fumes created by painting, soldering, or welding, which have been known to cause headaches, dizziness, and serious health issues

We have provided metal downdraft tables to clients in different industries across North America. For example:

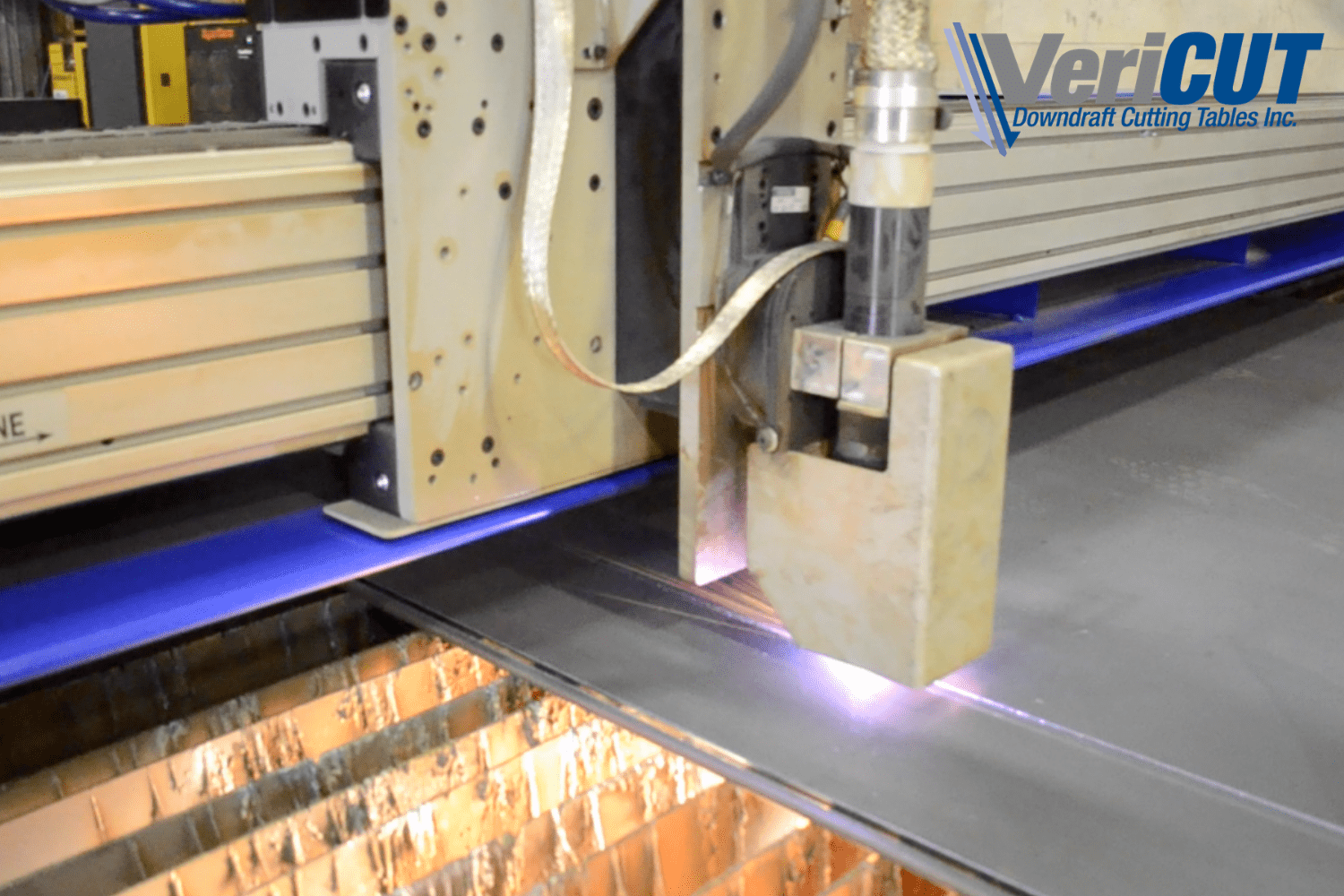

- A 24’ x 13.3’ downdraft system was shipped to Illinois to grace the showroom of a high-profile client. The signature VeriCUT design, combined with a slat frame concept developed by the client, allows lasers to cut through two-inch thick steel plate using up to 10 kilowatts of power, all the while clearing the surrounding air of harmful pollutants.

- This 16’ wide x 66’ long downdraft table system was manufactured to meet the needs of a client’s operation in Minnesota. Their employees can operate the cutting machine without worrying about exposure to airborne toxins.

- This super-sized 12’ x 200’ system supports multiple-machine plasma cutting and beveling. Productivity remains high without compromising indoor air quality. We can design a system to meet the most unique or demanding applications.

With a downdraft table in place, your workforce will thrive in a dust-free environment, which means fewer sick days and lost production time due to air quality issues. Everyone will be able to breathe easier (including you!) and your operation will realize both short and long-term cost savings.

Contact a trusted Canadian downdraft table provider

At VeriCUT, we design, manufacture, and install metal downdraft tables that can eliminate harmful dust generated by workstations dealing with wood, metal, plastics, composites, and welding. Each table is custom-designed to meet the ventilation needs of your facility, so your exposure to harmful dust particles will be limited and everyone on the premises will breathe in cleaner, purer air. To schedule a consultation to discuss your dust collection needs, please contact VeriCUT Inc.

October 13, 2020