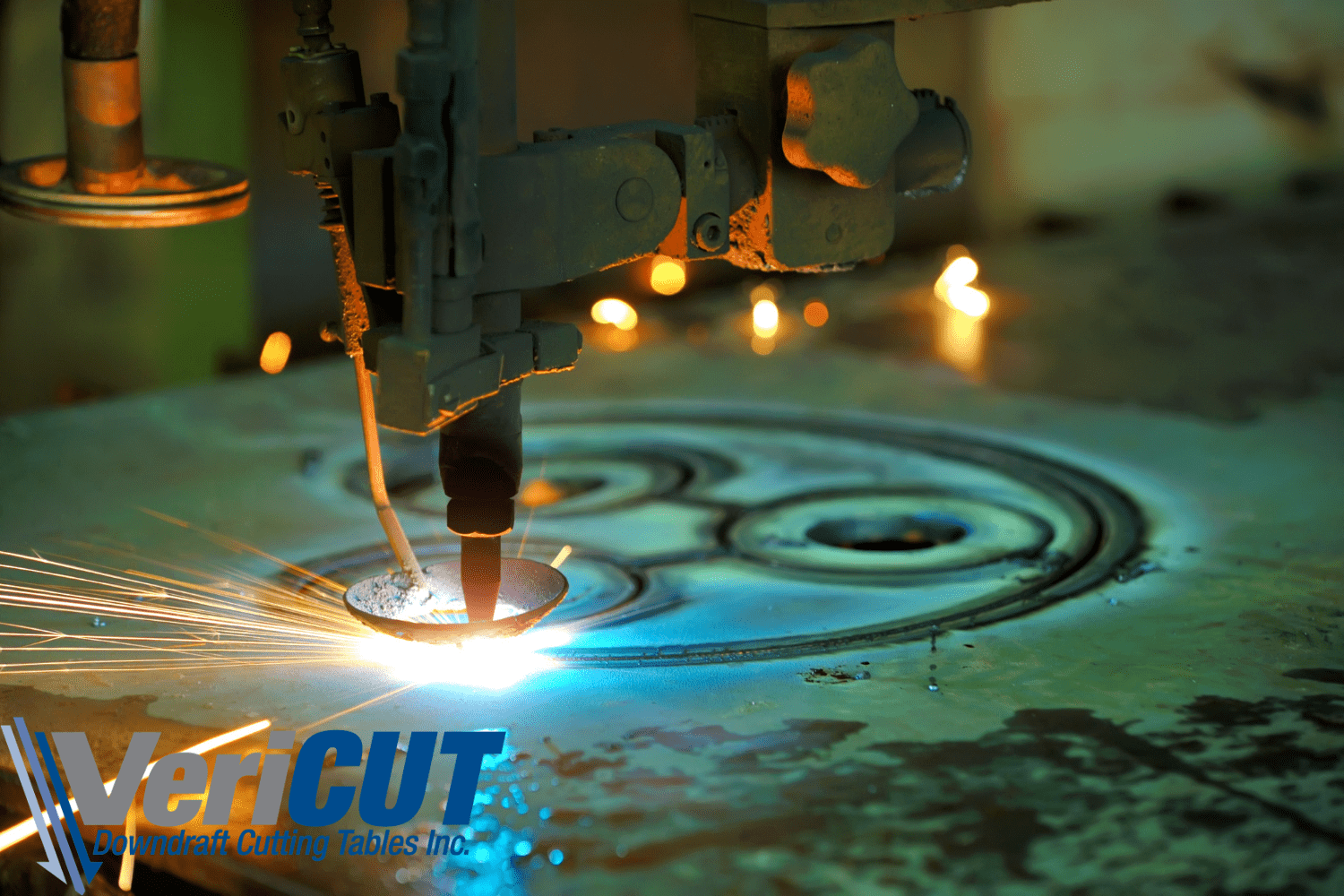

Downdraft tables are useful for any type of machining, including plasma cutting. Take a closer look at how these tables can improve your plasma cutting.

A Brief Introduction to Downdraft Tables

Downdraft tables are a type of workbench that includes ventilation built into the unit. This ventilation is designed to bring smoke, fumes, and dust away from the current project as well as the person working on it. Most downdraft tables achieve this goal with perforations connected to a dust collection system or ventilation that draws the materials like smoke and dust away.

Benefits of Downdraft Tables

From health to efficiency, downdraft tables are associated with a number of benefits. Overall, these tables can improve various aspects of the work area.

- Fire minimization benefits: Some excess dust, like oxy-acetylene and plasma, could start a fire. By controlling this dust, downdraft tables reduce the risk of fire.

- Health benefits: Breathing in the smoke and dust present without a downdraft table can lead to long-term health issues. These include continuous coughing, throat and lung cancer, asthma, eye irritation, and more. Therefore, downdraft tables protect employees from these health problems. Businesses can also avoid expenses related to sick employees, such as workers’ compensation claims and training of new workers.

- Legal benefits: Downdraft tables help employers provide a safe, clean workspace, showing compliance with the OSHA and other regulations.

- Monetary benefits: The reduction in fire risk and improvement in employee safety associated with downdraft tables frequently leads to lower insurance rates.

- Productivity benefits: Having a clean and safe working space improves productivity. Visibility and accuracy are higher, helping employees work more efficiently with fewer mistakes. There is less time wasted on cleaning, and workers need fewer breaks to cough or clean their safety glasses.

- Quality benefits: Having dust in the air can result in poorer quality work, such as when dust ends up in paint booths. This can require rework, lead to an increase in products not up to quality standards, and lost clients.

How They Can Help in Plasma Cutting

When it comes to plasma cutting downdraft tables, you will notice many of the above benefits, including improving the quality of the work and productivity.

About Plasma Cutting

Plasma cutting uses jets featuring hot plasma to cut through electrically conductive materials. It is suitable for cutting copper, brass, aluminum, stainless steel, and steel.

Just some of the common uses of plasma cutting include fabrication, auto restoration and repair, salvage, scrapping, and industrial construction.

Why It Is Used

Plasma cutting is commonly used because of its ability to deliver precise cuts at high speeds while maintaining low costs. Overall, plasma cutting provides a range of benefits, including:

- Automation: Plasma cutting allows for automation.

- Improved speed: Plasma cutting is twice as quick as using oxyfuel, with 2-inch-thick metal. It even has a higher cutting speed when used with thinner metals. Plasma cutting can increase the speed by 12 times or more.

- Improved speed for inside piercing: Plasma cutting also increases the speed of cuts for interior piercing.

- Less dross: The dross or oxide slag from oxyfuel cutting sticks to cuts, requiring grinding or chiseling to get off. By contrast, the high-temp gas in plasma cutting is electrically charged and removes this molten metal from the cuts.

- No (or less) plate warping: Plate warping is a common issue with thin materials cut with other methods, but not with plasma cutting thanks to the fast speeds involved, which limit the exposure to heat.

- Safe: Plasma cutting relies on non-flammable gas, making it safer than processes using flammable gases.

- Underwater option: You can also set up plasma cutting to take place underwater, further reducing the noise and heat exposure.

- Versatility for materials: Plasma cutting is also versatile enough to work with a full range of electrically conductive materials, including all non-ferrous metals.

How a Downdraft Table Can Help

Using a plasma cutting downdraft table combines many of those benefits of a downdraft table with those of plasma cutting. One of the biggest benefits is the ability to improve the quality of the cuts, combined with a boost to productivity.

The downdraft table removes fumes and particles that can interfere with visibility while using plasma cutting. That lack of visibility slows down productivity while reducing the accuracy of cuts. By contrast, with a downdraft table, workers can clearly see the area, making it easier for them to create precise, accurate cuts and, therefore, improve productivity.

Compared to the common alternative of using water to control fumes from plasma cutting, downdraft tables are easier to clean, cost less initially, eliminate the issue of rust, and improve the quality of the cuts on steel.

To start taking advantage of the benefits that a plasma cutting downdraft table provides, explore the VeriCUT website. You’ll learn more about our services, including creating custom downdraft tables to enhance your plasma cutting.