It can be hard to maintain the air quality in your machine shop. Therefore, you may want to consider purchasing a professional-grade customized downdraft table from VeriCUT. A high-quality industrial downdraft table equipped with a shop dust collector will address and remedy your shop’s issues with poor air quality.

How Do They Work?

VeriCUT downdraft cutting tables pull the smoke, dust and contaminants in the air down and away from your breathing space. The duct has the same air draw, no matter where the cutting torch is across the width or length of the table. The table can pull in and remove smoke from as far as two to three feet above. As a result, the table removes the hazardous smoke and particles that are generated near your source and avoids contaminating your shop.

What You Can Use Them For

Industrial downdraft tables are perfect for removing both fumes and dust from your air during many or your shop’s different applications. These include, but are not limited to, polishing, grinding, cutting, welding, and sanding your metal products. You can use them when during applications as:

- Sanding: It is now easier for you to achieve a smooth finish on your products without causing fine dust particles to spread throughout your shop.

- Welding: You can use an industrial downdraft table for applications that are more involved, such as MIG and TIG.

- Deburring: This is beneficial when using abrasives to finish or polish materials that have been fabricated.

- Grinding: This is done to remove bits of refuse from your plastic and metal grinding.

- Mixing: Shop dust collectors are used when mixing in order to stop granules and powders from escaping into the air.

- Cutting: The shop dust collector is perfect for plasma cutting and can improve your health and safety by removing the dust and fumes released into the air that you’re breathing in.

Benefits of Using an Industrial Downdraft Table

When you are soldering, welding, painting, etc. it is important that you do not inhale the resulting particles. Otherwise, you may experience health effects such as, headaches, dizziness, and in some more severe cases, permanent lung damage. Using an industrial downdraft table can help you capture and eliminate toxic gases, fumes, smoke, and fine dust particles right at the cutting source.

Fine dust particles are nearly impossible to see without using magnification. Therefore, you may be unaware of how much dust is polluting the air quality in your shop. It is important to remember that dust can still enter your body if you are wearing a mask and it can cause many acute or chronic health conditions for those who inhale dust on a regular basis.

As fine dust particles settle in your lungs, they can impair the functionality of your lungs. Eventually, this can cause inflammation and scarred tissue within your body. The effects are particularly problematic when the dust enters your bloodstream through your lungs and affects your brain, kidneys, and liver, which will undoubtedly lead to chronic and acute health conditions. If left untreated, you may require medical attention and in many cases the damage cannot be reversed.

VeriCUT’s industrial downdraft tables achieve significantly superior productivity and cost savings by utilizing a zone-by-zone ducting design that provides localized smoke removal right at the cutting source. This means that the dust collection system is only drawing smoke in from the area being used, resulting in:

- Lower air make-up costs

- Higher dust recovery rates

- Smaller dust collection system required

- Better ROI on your equipment

In addition, because the industrial downdraft tables are 100% mechanical, maintenance and repairs are rarely required.

Closing Thoughts

The VeriCUT industrial downdraft tables are arguably the most energy-efficient tables currently on the market. If you’re interested in learning more about industrial downdraft tables, or are thinking about purchasing one for your shop, please contact VeriCUT today.

Using a duct collector in Ontario is a great way to improve the quality of the air in your shop. However, many people may not be aware of the additional benefits of dust collectors. VeriCUT offers high-quality dust collectors and proudly serves businesses across North America. This blog will explain how dust collectors work and will provide tips in regards to how to choose the right one for your needs.

What Are Dust Collectors?

Dust collectors in Ontario can improve the quality of the air in your shop during mechanical, metalworking, woodworking, and commercial and industrial processes. More specifically, the VeriCUT system removes fine dust particles from the air, as well as other airborne particles and impurities by drawing them back into the table.

The downdraft cutting tables have special slotted air ducts in them, which can help you efficiently extract the particles from the air. When the cutting machine is idle, the speed of the motor in the fan of the dust collector will be reduced. With the wireless connection, the pre-programmed instructions will look at the machine’s variables and report both the stats and the machine’s status. This can result in an 80 percent reduction in heat and electricity loss.

What Companies Use Dust Collector Systems for

Previous studies have shown that fume and dust-producing operations do not achieve more than 30% of operating time. On the other hand, your dust collection system may operate around the clock. That means that with a traditional system, you are wasting as much as 80% of your electricity.

However, with the VeriCUT system, the motor that controls the dust is either shut down or scaled back when it’s not in use. This allows you to control both your costs and the parameters, saving up to thousands of dollars each year.

You can usually see a return on your investment in approximately seven and a half months. The types of businesses that can benefit from a dust collector in ontario include:

- Woodworking Shops

- Agricultural, Food, and Chemical Companies

- Companies That Use Plasma- and Laser-Cutting Tables

- Pharmaceutical Businesses

- Businesses That Use Any Other Process That Produces Fumes or Dust

About Our President

Paul Rak is the president of VeriForm Inc., which is a metal fabrication company established more than two decades ago. Rak has a Bachelor of Science in biology from the University of Western Ontario. He also attended the University of Waterloo to learn about business management. He is a member of the Regional Sustainability Initiative in the Waterloo Region and often speaks on topics that relate to sustainability for different companies as an expert on going green.

Rak founded VeriCUT in 2001 with a focus on creating downdraft tables for the water-, laser-, and plasma-cutting sectors.

Why Choose VeriCUT?

VeriCUT is passionate about providing equipment that will improve the quality of air in your shop and productivity while lower operating costs. VeriCUT created the Crossflow Downdraft Cutting Table to eliminate dangerous dust and smoke during the plate cutting process. It is currently one of the top tables in North America for eliminating smoke and dust.

VeriCUT also has a commitment to being an accessible company. The company has made it a priority to implement policies and practices for people with disabilities. They have a special hiring process that accommodates candidates with disabilities during interviews, the selection period, onboarding and training.

While the company’s physical location is in Kitchener, Ontario, VeriCUT, Inc. is proudly serving businesses across North America. If you’re interested in learning more about VeriCUT, please contact us today. Our experienced and knowledgeable team will be happy to provide you with more information about VeriCUT, our products, services and dust collectors.

There are a lot of compelling reasons to buy products made in Canada. They range from the reduction of environmental impact to the preservation of local jobs and the overall economy. As consumers, however, we don’t always think about how our buying decisions affect the communities we live in. Many of us tend to look for lower-priced products made outside of Canada and opt to save money instead of invest in high-quality items made locally.

When COVID-19 took hold, that mindset started to change. Canadians became more conscious of where products were coming from and started letting patriotism guide their purchasing decisions. It’s a positive trend that needs to continue, whether you’re buying a dining room set or a dust collector.

Why Shop For A Dust Collector In Canada?

When you buy your dust collector from a Canadian company, the benefit goes well beyond the profits realized by the business. You can rest assured that you are getting a product that-

- Meets this country’s high health and safety standards. The Canadian manufacturing industry is highly regulated, so all dust collectors made here come from factories where quality assurance practices are superior and only the best materials are used.

- Reduces your carbon footprint, as locally-built products don’t have to be transported as far. Less gas used means better environmental quality.

- Was made in a facility where the employees are treated fairly and enjoy safe and sanitary working conditions, unlike those working in sweatshop conditions overseas.

- Supports your community. When you shop for a dust collector in Canada, you contribute to the ongoing prosperity of a Canadian-owned and operated business, and keep local people employed.

- Lets you avoid the hidden additional costs of duties and import fees. Plus, you receive the equipment much sooner.

- Has local aftermarket support if you encounter any difficulties.

Buying Canadian also has a direct and positive impact on our economy. Every dollar you spend here has a ripple effect: you participate in the creation and support of local manufacturing jobs, which employ workers who pay taxes and spend money that maintains a healthy local, provincial, and national economy.

Meet VeriCUT- Proudly Canadian!

At VeriCUT, we are 100% Canadian-owned and operated. Guided by our President, Paul Rak, who is a proud Canadian, we manufacture innovative dust collection solutions at our 26,000 sq ft. facility in Cambridge, Ontario. Powered by our wholly-Canadian workforce and dedicated to customer success, we have always been committed to the following principles:

- Supporting the community: Together with our sister company, VeriForm, we empower local businesses to encourage community prosperity.

- Sustainability: We make careful and conscious decisions about energy use at our facility. Since 2015, we have also acquired carbon offsets from Canadian sources to stay carbon neutral.

- Education: We believe in using education to empower our employees, customers, and the local community.

- Accessibility: We develop and implement accessible policies, practices, and procedures for the disabled and our hiring practices accommodate disabilities during the selection process.

Our dedication to superior customer service is manifest in our industry-leading dust and fume collection equipment. The VeriCUT Crossflow Downdraft Cutting Table has contributed to safer and more sustainable workplaces everywhere by eliminating the dust and smoke hazards created during plate cutting while minimizing the amount of energy used during daily operations. Other systems run 24-7, incurring energy costs that don’t contribute to your profitability in any way, but VeriCUT dust collectors only operate when you do, saving you up to 70% in utility costs.

When you buy from us, you get a dust collector with a mechanical design that needs virtually no repairs, protecting your operation from unexpected downtime and reduced productivity. You also benefit from the knowledge and expertise of our technicians and the best customer service in the industry. When you buy Canadian, we believe in making sure that you’re 100% satisfied with your investment.

Contact a Trusted Canadian Provider

If you want to shop for a dust collector in Canada, contact VeriCUT Inc. By partnering with a Canadian company that’s committed to product excellence and greater sustainability in manufacturing, you can enjoy the benefits of a safer workplace with lower operating costs, while the community prospers thanks to your investment.

What if energy saving could ensure the survival of your business? 14 years ago, Paul Rak, owner of the metal processing…Posted by Pivot on Monday, June 8, 2020

WHAT WE OFFER:

- Cutting of a variety of metals including Steel, Stainless and Aluminum.

- Processing of steel from 18GA (0.050”) up to 1.50” thick.

- Handle cutting VERY large parts on our 120” x 300” VeriCUT Table

- Fast turn-around times, usually within 3 to 5 days.

- Excellent weld-ability and smooth edge quality.

- Production cutting of parts at a reasonable cost compared to laser & waterjet especially for very thick metals.

- Advanced nesting and CAD software to maximize steel utilization to lower your costs!

VeriForm has always offered production cutting of steel up to 1.5” but with our newly installed Messer MetalMaster Evolution Plasma System, we can offer even higher quality plasma cut parts at a reasonable cost.

Benefits of VeriForm Plasma Cut Parts

- Large Cutting Table for your Very Large Parts

We specifically designed our VeriCUT Downdraft Cutting Table to be able to fit up to a 10ft x 25ft” long plates. This allows us to cut very large and long parts while still holding excellent tolerances.

- High Definition Plasma Excels at Cutting Thick Steel

Our new Messer Evolution machine can cut up to 1.5” thk metals including Stainless and Aluminum. Our advanced VeriCUT Down draft table system extracts fumes, smokes and dust to conform to all health and safety requirements.

- Ability to cut a Wide Variety of Material

We have achieved considerable success cutting aluminum and stainless from 3/8” to 1” thick. Our high definition plasma system produces quality stainless & aluminum parts without the high cost of water jet cutting.

- Smooth Edge Quality & Excellent Weld-ability

Only cutting with pure Oxygen, VeriForm plasma cut parts eliminates nitrating & porosity and allows welders to weld parts together without having to grind the cut edges. Unlike some laser cut parts, high definition plasma achieves a more weld friendly cut surface and avoids laser-oxide build-up of cut edge surfaces.

- Competitive Cost for your Parts

Our new High Definition Plasma is faster, more productive process than laser, waterjet or oxyfuel cutting when doing mechanized cutting greater than 6 mm (1/4”) and less than 50 mm (2”). Our advanced Sigmanest nesting software allows us to achieve minimal scrap which saves you money!

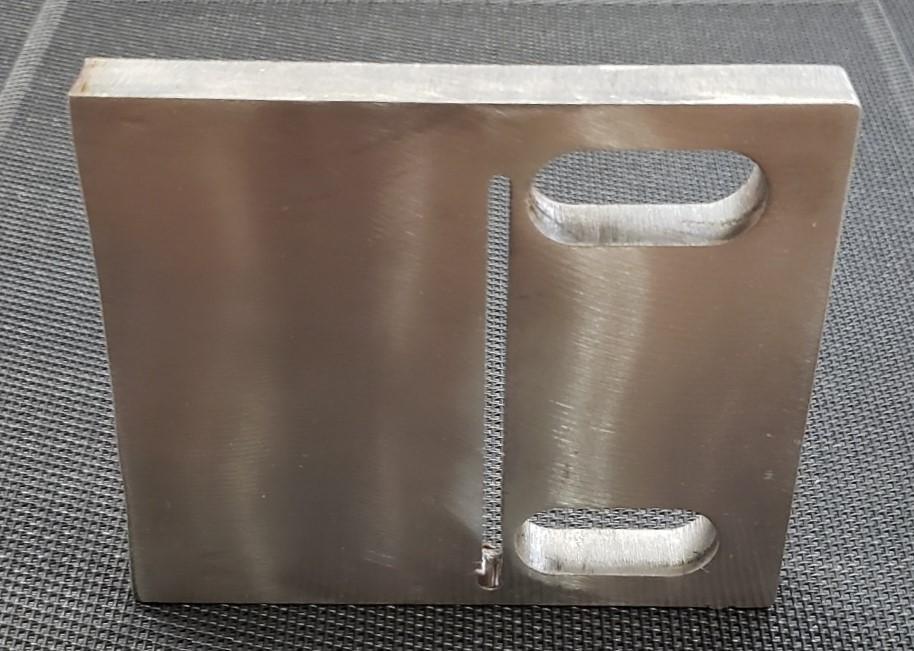

Please see below some samples of Plasma Parts:

Give us a call OR send us your CAD/Drawings for a quote today!

If you operate a facility that handles powder and bulk solids, you’re probably generating hazardous levels of dust. In addition to being a general nuisance, very fine particulates can get into the lungs and cause serious health issues while certain types of dust, such as wood, grain, and metal, are a fire and explosion hazard.

With worker and site safety being paramount, your dust collector is an essential part of facility operation. This means that if it needs repairs or maintenance, you have to temporarily shut down production until the system is back online. Depending on how long work has to be halted, you can lose a lot of profit and productivity, and dust collector repair costs can add up.

If your current dust collector has needed frequent repairs, you may assume that these expenses and downtime are a frustrating but necessary part of a busy operation. The good news is that there is a dust collection system that needs practically no repairs and can even save you money on your utility bills.

The VeriCUT Solution

VeriCUT downdraft tables are 100% mechanical systems, which means that your dust collector repair and maintenance needs are virtually zero. Unlike a lot of other systems on the market, they only require cleaning two or three times a year, so planned downtime is minimal and can be scheduled at a time that will have the lowest impact on productivity.

Operating Benefits

VeriCUT dust collectors use a specially engineered ducting system that ensures a consistent smoke draw across the entire width of the cutting table. Even smoke that is 2-3 feet above the table can be drawn back down, protecting the shop from smoke and dust accumulation. Smoke is only drawn from the immediate work area, so operating costs are reduced while your workers stay safe during cutting operations.

Other benefits include:

- No hidden overhead costs: VeriCUT dust collectors incur zero air and electrical utility expenses when not in operation.

- Custom design/build available to provide you with a downdraft table sized for your production needs.

- The system has a modular design, so you can make the table longer by adding extra sections. There is no need to buy a new, larger downdraft table.

- Retrofit is available for existing installations.

- Jig attachments are available for structural steel jobs that call for specialized cutting.

- Customized pallet system makes material handling easier and more efficient.

- Unique optional features available, such as under-the-table hidden caterpillar tracks for tight spaces.

The ability to customize ensures that there is always a VeriCUT system for your operating requirements.

Cut Dust Collection Costs!

Although cutting machines, saws, grinding machines, and other equipment that generate dust and fumes seldom operate for over 30% of a production shift, dust collectors run constantly. This means that you’re paying for energy usage that doesn’t contribute to your bottom line.

A case study found that a plasma cutting table with a 13,000 cfm, 40hp VeriCUT dust collector used 70% less power than another, similar system. (Both systems were installed in facilities with an 80-hour workweek.) The other dust collector had a yearly energy cost of $13,124 while the VeriCUT unit incurred only $3,937 in energy bills, representing a cost savings of $9,187!

Heat savings were equally impressive. While the other system had an annual heating cost of $6,160, the VeriCUT technology only cost $1,848: a difference of $4,312.

Why such a massive difference in utility costs? The VeriCUT system has a dust control variable motor that automatically scales back when operations are shut down. Operators can also input their own set-back parameters to control energy use and save money. A typical first-year return on investment (ROI) is 161%.

Contact a Trusted Canadian Provider

At VeriCUT, we are proud of our reputation as manufacturers of leading industrial dust and fume collection systems. By offering high-performance and energy-efficient dust collectors that need no expensive repairs, we help you address combustible dust hazards and improve the quality of indoor air, making your facility a safer and more productive place to work. To schedule a consultation and identify a system that will quickly become a major asset to your business, please contact VeriCUT Inc.

When you run a business that creates dust either as a product or as part of the manufacturing process, your employees and facility are at risk. For example:

- Fine dust particles can enter the respiratory system, aggravating allergies and potentially causing lung damage.

- Dust can accumulate on surfaces that can be hard to reach and clean, such as rafters or false ceilings. A dangerous combination of high quantities and a combustible nature can lead to dust fires and explosions.

Dust collection is a critical issue in Ontario businesses that produce or work with raw materials, such as wood pellet plants, pulp and paper mills, and metalworking shops. There have been several incidents across the province in recent years, including a paper mill fire in Thunder Bay. Installing a modern and efficient dust collector in your facility can help you avoid business interruption and save lives.

How Does A Dust Collector Work?

Dust collectors have a single operating protocol: dirty, dust-laden air goes in and clean air goes out. The actual process will vary according to system type, which is important when you’re shopping for dust collectors in Ontario, but in general, they draw dust from the air through a filter, which captures all particulates before releasing healthy air into the facility or the environment. Basic components include:

- Blower

- Filter

- Filter cleaning system

- Dust holder

- Dust removal system

Automatic downdraft tables are another form of dust collection system. These workbenches have built-in ventilation systems that draw dust, fumes, and smoke away from employees working in shop applications involving plasma, metal, wood, and other dust-generating products.

Before buying a dust collector in Ontario, confirm that the dust control variable motor can be scaled back after shutdown and resume regular activity when needed. Although dust collection systems are constantly in operation, studies have shown that they are rarely in use more than 30% of the time your employees are at work. The right system will deliver the protection you need without incurring unnecessary energy costs.

Need More Information About Dust Collectors In Ontario?

If you operate in any of the above-referenced industries, installing dust collectors in your Ontario facilities can create a healthier workplace and prevent devastating events like fires and explosions. At VeriCUT Inc., we provide manufacturers of all backgrounds with the advanced and high-performance equipment needed to eliminate dust hazards. To schedule a consultation about your unique needs, please contact us.

When you run a shop or other business that produces dust on a daily basis, a dust collector that breaks down frequently can threaten the health and safety of your employees. Even if it doesn’t stop at the worst possible moment, plugged filter bags can cause the fans to work harder and faulty valves can leak compressed air, causing your utility costs to shoot up.

The best solution to these manufacturing challenges is a dust collector that needs virtually no maintenance or repairs. Enter VeriCUT.

VeriCUT vs. Other Systems

VeriCUT dust collectors are specially-designed to offer the most efficient dust extraction in the industry. Its zone-by-zone ducting system only draws smoke from the immediate area of cutting work being done, instead of across the entire table, resulting in a smaller dust collection system that offers higher dust recovery rates and a superior return on investment.

VeriCUT is compatible with practically all applications that produce fumes or dust, including:

- Woodworking

- Metalworking

- Food processing

- Chemical processing

- Pharmaceutical

- Plasma cutting

Efficient operation ensures, among other things, that your dust collector repair costs are practically zero and you save money on utility bills.

Utility Cost Differences

One case study involving a plasma cutting table with a 13,000 cfm, 40hp dust collector showed the impacts on utility costs:

- Compared to other 40 hp dust collectors in facilities operating 80 hours a week, there was a 70% reduction in power consumption, resulting in electricity savings of $9,187 per year. (The VeriCUT system cost only $3,937 to operate while the other system cost $13,124).

- In terms of heat savings, the VeriCUT system cost only $1,848: a difference of $4,312 compared to the annual heating cost of $6,160 incurred by the other system.

The cutting table without a VeriCUT dust collector had an overall annual utility cost of $19,284, compared to $5,785 in the unit where VeriCUT had been installed.

Why such a huge difference? Although operations that generate dust and fumes seldom account for over 30% of a facility’s operating hours, most dust collection systems operate 100% of the time, resulting in waste of electricity that can be as high as 80%. With VeriCUT, the dust control variable motor automatically scales back on shut down. You can also specify the set-back parameters to achieve an ideal balance of system-readiness and energy-efficiency.

Return On Investment (ROI)

Although VeriCUT may be more expensive than other dust collection systems, its robust system, which requires virtually no maintenance or dust collector repair, produces a typical first-year return on investment (ROI) of 161% while the 10-year ROI is 1600%. This is one of the best demonstrations of that old saying, “You get what you pay for.”Installing a VeriCUT dust collector is a significant investment in the future success of your business. To schedule a consultation or learn more about how we can help you strengthen your bottom line, please contact VeriCUT Inc today.

Dear Valued Customers & Vendors,

As we, at VeriForm Inc. and Caliber Tech Corp., are monitoring the ever-changing climate of the pandemic, including communications following Government guidelines, we would like to inform you of our efforts to manage and combat the Covid-19 virus situation. Effective as of March 9th 2020, VeriForm Inc. and Caliber Tech Corp. put into place the following preventative measures in our facility.

Firstly, any employee who chooses to travel via a commercial airline or cruise ship is required to remain at home for 14 days upon their return. Furthermore, any employees showing signs of illness will not be allowed to return to work until medical clearance is obtained. We have trained our staff on understanding the 3 key symptoms of difficulty breathing, coughing and fever to ensure staff quarantine themselves should any staff experience Covid-19 symptoms. Social distancing, staggered lunchroom breaks, sanitizing work areas and other procedures are in full effect to help us minimize any chance of transmitting or being infected with the virus.

Secondly, we are working closely with our employees and drivers to ensure frequent hand washing and proper hygienic measures are followed. Sanitation of all high-touch surfaces in our office, workshop and break room are being carried out throughout the day including machinery, instruments, appliances, tools etc.

Thirdly, we have temporarily suspended any unnecessary face to face visits/meetings with customers and vendors.

We are doing everything we can to protect our workforce and to minimize any disruptions to our manufacturing process. Thus far, both our plant and our raw material supply chain remain unaffected and, at this time, our lead times remain relatively stable.

The health and safety of our team, families, customers, and communities continues to be our highest priority moving forward, and we will do everything we can to respond to the current events while continuing to maintain exceptional service.

Thanks,

Paul Rak

VeriForm Inc.

Dust collection is an essential part of any industry that processes raw materials, especially if it produces combustible dust. Many woodworking, grain processing, and metal manufacturing facilities install dust collection systems to keep the premises clean and protect property and personnel from hazardous situations like dust fires and explosions.

While they play a critical role in workplace safety, dust collectors also pose a fire risk. Those who are familiar with the Fire Triangle know that there are three elements which must be present for a fire to occur. These are:

- Fuel

- Oxygen

- Heat

Dust collectors collect fuel on a regular basis: they’re constantly pulling combustible dust off the tables, floors and fixtures. As they suck in the dust, they also bring in oxygen at a high velocity, which means air is constantly circulating through the system. If heat is also generated, the could result in a fire.

How can heat be created in a dust collector?

Depending on the industry, there are several things that can produce sufficient heat to cause a fire. In a metalworking or automotive plant, for example, sparks generated by welding or cutting machines can be pulled into the dust collector, where they may hit the filter media and ignite. Sawmills and paper mills face similar risks. Even an ember from a carelessly discarded cigarette can trigger a series of events that lead to a dust fire and potentially an explosion.

Are handheld fire extinguishers enough?

Although many businesses use handheld fire extinguishers, this common firefighting tool carries its own potential risks. When you’re manually fighting a dust collector fire, you need to shut the machine down and wait the recommended amount of time (typically 30 seconds) before opening it to access the burning interior. However, doing this can allow more oxygen into the system and create a larger fire, leading to employee injury and equipment damage.

The benefits of an automatic fire suppression system

When you have an automatic fire suppression system in place, no employee needs to try extinguishing a dust collector fire themselves. As soon as the fire is detected, the system releases a suppression agent and puts it out before an explosion can occur. If you have explosion protection in place, this suppression system can also eliminate any residual fire after an event takes place. Your employees, equipment, and facility are safe. At VeriCUT Inc., we can help you increase safety and efficiency by installing a downdraft table and dust collector system that eliminates dust, smoke and fumes and prevents dust fires from escalating to deflagration stage. We serve a variety of industrial applications, so contact us to learn more.