WHAT WE OFFER:

- Cutting of a variety of metals including Steel, Stainless and Aluminum.

- Processing of steel from 18GA (0.050”) up to 1.50” thick.

- Handle cutting VERY large parts on our 120” x 300” VeriCUT Table

- Fast turn-around times, usually within 3 to 5 days.

- Excellent weld-ability and smooth edge quality.

- Production cutting of parts at a reasonable cost compared to laser & waterjet especially for very thick metals.

- Advanced nesting and CAD software to maximize steel utilization to lower your costs!

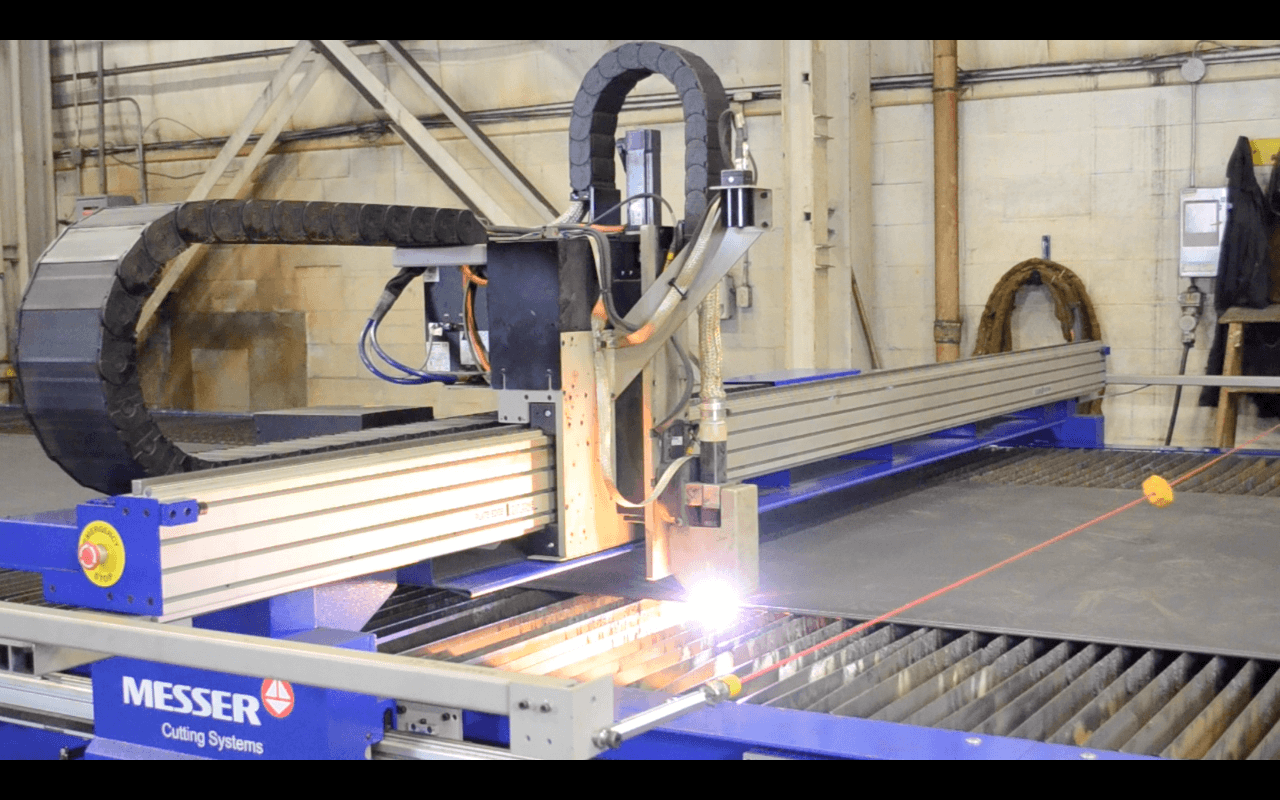

VeriForm has always offered production cutting of steel up to 1.5” but with our newly installed Messer MetalMaster Evolution Plasma System, we can offer even higher quality plasma cut parts at a reasonable cost.

Benefits of VeriForm Plasma Cut Parts

- Large Cutting Table for your Very Large Parts

We specifically designed our VeriCUT Downdraft Cutting Table to be able to fit up to a 10ft x 25ft” long plates. This allows us to cut very large and long parts while still holding excellent tolerances.

- High Definition Plasma Excels at Cutting Thick Steel

Our new Messer Evolution machine can cut up to 1.5” thk metals including Stainless and Aluminum. Our advanced VeriCUT Down draft table system extracts fumes, smokes and dust to conform to all health and safety requirements.

- Ability to cut a Wide Variety of Material

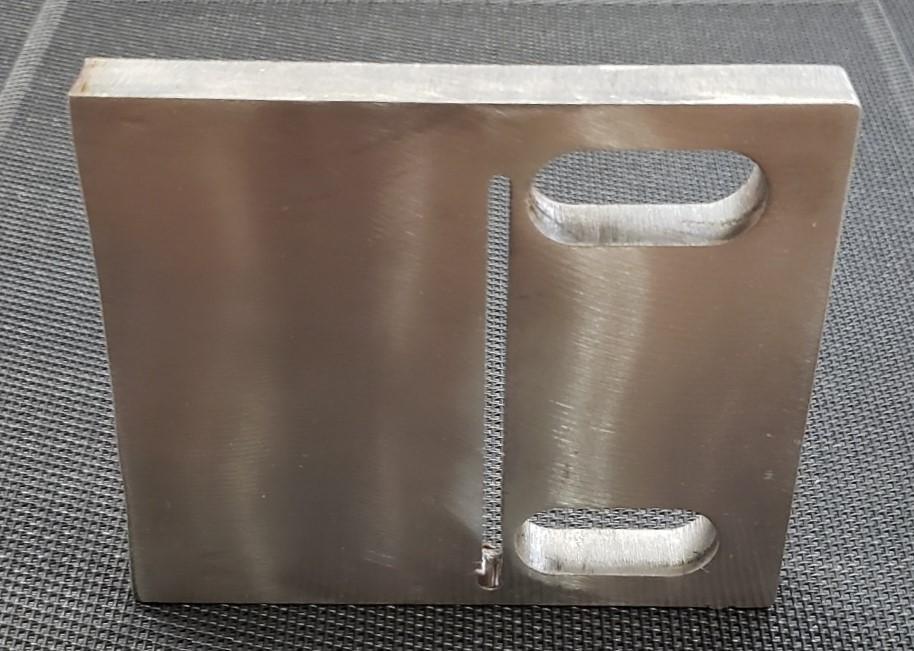

We have achieved considerable success cutting aluminum and stainless from 3/8” to 1” thick. Our high definition plasma system produces quality stainless & aluminum parts without the high cost of water jet cutting.

- Smooth Edge Quality & Excellent Weld-ability

Only cutting with pure Oxygen, VeriForm plasma cut parts eliminates nitrating & porosity and allows welders to weld parts together without having to grind the cut edges. Unlike some laser cut parts, high definition plasma achieves a more weld friendly cut surface and avoids laser-oxide build-up of cut edge surfaces.

- Competitive Cost for your Parts

Our new High Definition Plasma is faster, more productive process than laser, waterjet or oxyfuel cutting when doing mechanized cutting greater than 6 mm (1/4”) and less than 50 mm (2”). Our advanced Sigmanest nesting software allows us to achieve minimal scrap which saves you money!

Please see below some samples of Plasma Parts:

Give us a call OR send us your CAD/Drawings for a quote today!

June 19, 2020