Downdraft cutting tables are gaining in popularity as an effective and sustainable method of dust and smoke collection and removal, particularly in plasma and laser cutting applications. While the plate is being cut, a blower pulls air out of the enclosed table underneath, preventing unhealthy smoke from escaping into the building.

VeriCUT manufactures downdraft cutting tables with a zoned design, meaning that they are divided into sections (zones). A duct runs down the length of the table, with an opening in each zone where it pulls in smoke right at the cutting source. Our tables improve the air quality in manufacturing and production environments where dust and fumes are produced, with a smoke capture and removal rate of 99%. Because the system draws smoke only in the cutting area instead of across the whole table, no energy is wasted and you can save money.

The VeriCUT system also has a dust control variable motor that automatically scales back when your production lines are closed down for the day. Although dust collectors rarely operate for over 30% of a production shift, they run constantly, which means that you’re paying for energy that you’re not actually using. Our software allows you to specify your preferred set-back parameters, so that the system runs only when needed. One case study actually showed that a typical first-year return on investment (ROI) is 161%.

VeriCUT Crossflow™ Downdraft Cutting Table

The mechanical VeriCUT Crossflow™ downdraft cutting table is our premier product. It delivers high-efficiency dust and smoke removal during laser, plasma, and oxy-acetylene cutting operations. Your staff remain productive without being exposed to potentially harmful particulates, your shop stays cleaner and, because the system is 100% mechanical, you’re not looking at expensive cylinder replacement costs or hydraulic / pneumatic component repairs.

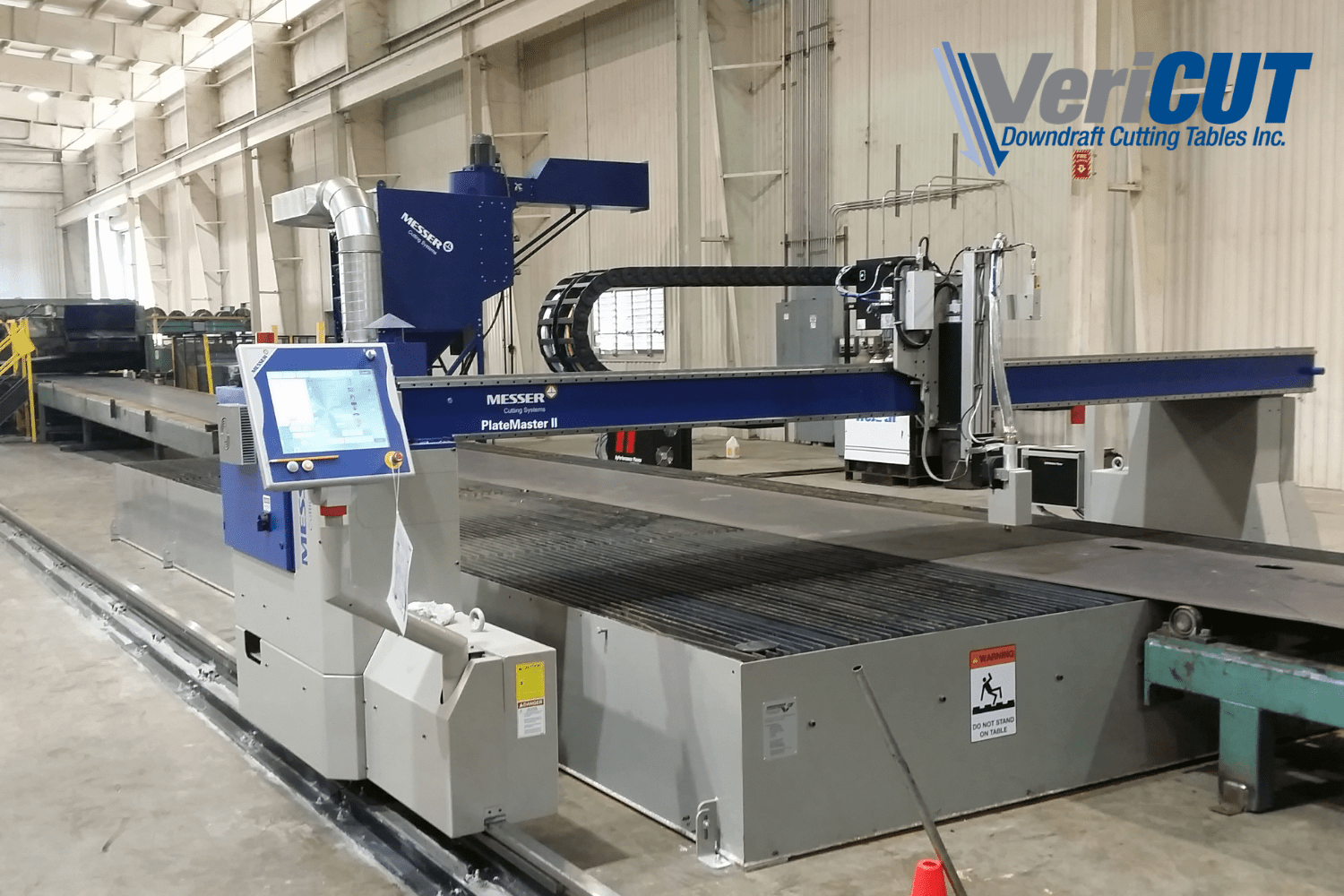

VeriCUT Downdraft Table with Messer MetalMaster Evolution

This exciting new technology combines our popular downdraft table with Messer MetalMaster Evolution to create a high-definition plasma cutting system. It can cut metal plates up to 1.5” thick, resulting in premium-quality aluminum and stainless steel parts without high expense associated with water jet cutting.

Other advantages include:

- A more weld-friendly cut surface that avoids laser-oxide buildup.

- By only cutting with pure oxygen, porosity and nitrating are eliminated, so welders don’t have to grind the cut edges before welding parts together.

- Our Sigmanest nesting software, which lets you save money by achieving minimal scrap.

VeriCUT Manual Downdraft Mini-Tables

If you run a smaller shop or use unique welding or handheld plasma cutting applications, VeriCUT can design, manufacture, and install a manual downdraft mini-table that delivers maximum smoke capture efficiency despite its minimal footprint.

Why You Should Invest in a Downdraft Cutting Table

The advantages of installing a high-efficiency dust collector in your workplace include:

- Improved workplace health and safety. Airborne dirt, gases, and chemicals can cause health issues and accumulate on surfaces, causing a fire or explosion hazard. High-efficiency dust collectors remove these pollutants from the air up to three feet above the worktable and reduce the risk of your employees becoming ill.

- Other equipment stays in good operating condition. When dust and debris collect on other equipment in your shop, it can get inside the gears and internal structures and affect the way these machines operate. Downdraft cutting tables will help your entire production line maintain optimal performance and limit expensive downtime.

- Product quality is preserved. It doesn’t take long for airborne dirt and dust to settle over newly manufactured products and parts and damage their quality. By keeping these contaminants out of the air, all of your shipments will arrive at their destinations looking brand new.

Because they play such a critical role in the health and safety of your employees, the last thing you need is emergency dust collector repair during periods of peak production. To ensure that your people and processes remain at top efficiency, invest in a downdraft cutting table that needs practically no maintenance or repairs. This is where VeriCUT can make a huge difference in your operation.

Contact a trusted Canadian downdraft table provider

By installing VERICUT dust collectors throughout the production floor, you’ll continue to meet quotas and deadlines while maintaining an environmentally-safe workplace. To learn more about how we can support your operation, please contact VeriCUT Inc.

September 30, 2020